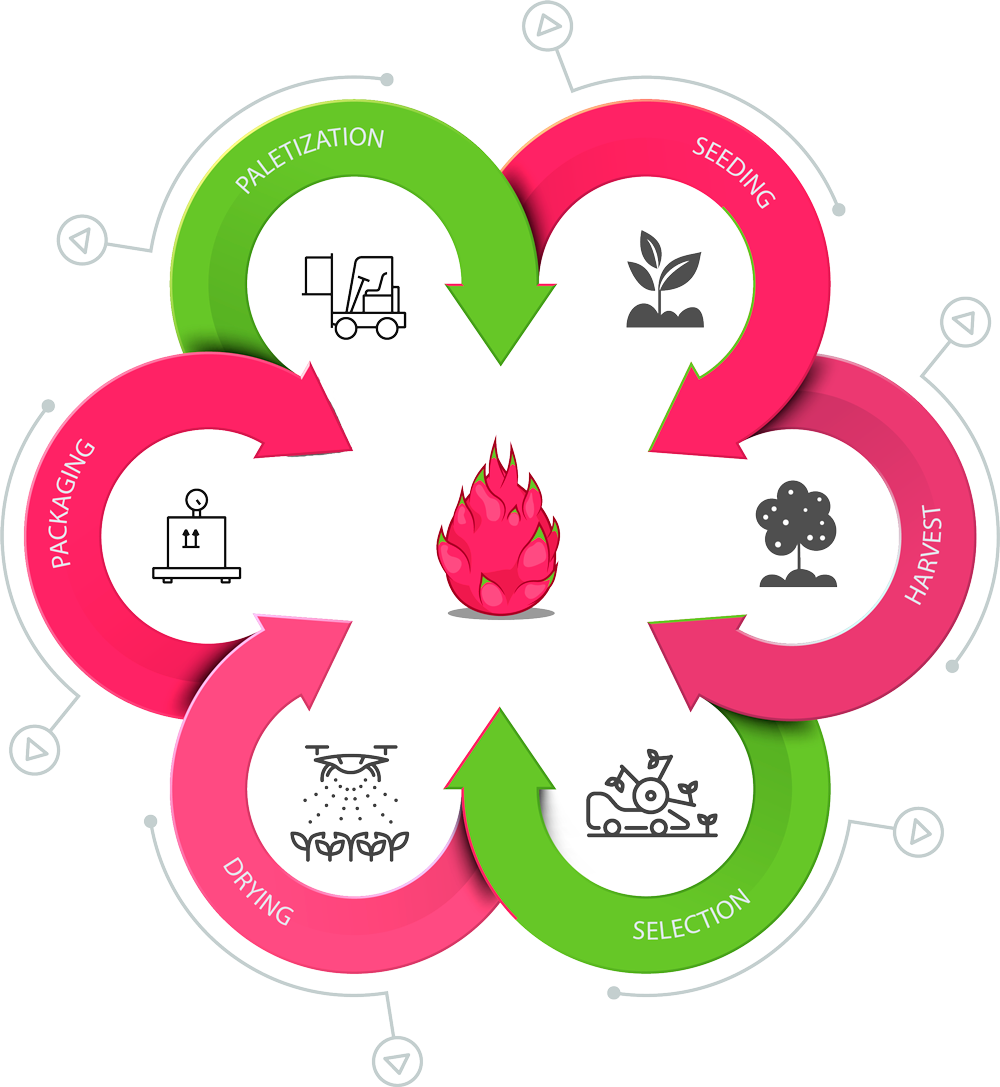

placed in a cold room ready to be

transported to the world via

maritime or air.

placed in padded boxes, and

then transferred to the plant to

prevent abuse and weighing.

one night. Each flower is pollinated by hand

30 days later after harvest comes.

by quality, weight, and measure. They are

separated based on those characteristics.

The export product is then separated starting

the traceability of the process (check the

chapel video has a special color), goes through

the process of being washed individually,

and then is placed in a sanitized sanitary.

Always keeping the fruit of the same batch in the

initial boxes.

pressure tunnels that dry the fruit so

they can be packed. They are coded

according to size and characteristics.

in which it was packed, the

day, and the code according

to USDA standards.